In the world of manufacturing, reverse engineering plays a crucial role in restoring legacy parts and enhancing existing designs. Simply defined, reverse engineering refers to the systematic analysis of a product to comprehend its internal workings and create a duplicate version without having access to its original blueprints or specifications. Companies often turn to reverse engineering when they need to replicate obsolete components, restore vintage vehicles, refurbish industrial machines, or even optimise current designs for better efficiency and durability.

Understanding Reverse Engineering at Thompson Precision

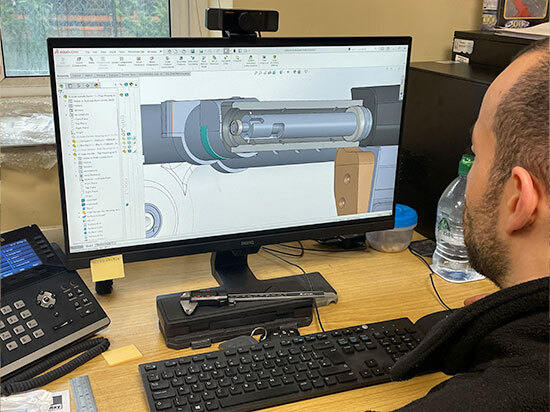

At Thompson Precision, we specialise in providing top-notch reverse engineering services, combining extensive experience, unmatched expertise, and state-of-the-art technology. Our team embraces intricate projects with enthusiasm, eagerly tackling any challenge thrown our way. Central to our approach is leveraging advanced laser scanning technology and powerful SolidWorks design software to accurately capture every detail of the item slated for reverse engineering. With years of hands-on knowledge guiding us, we transform raw scan data into precise 3D models tailored to meet your unique needs.

The Need for Reverse Engineering

There are several situations where reverse engineering is useful. One common scenario involves obtaining replacement parts for ageing equipment or discontinued products—known as legacy parts. When manufacturers stop supplying these components, organisations rely on reverse engineering to produce compatible substitutes, ensuring seamless integration and continued operability.

There are several situations where reverse engineering is useful. One common scenario involves obtaining replacement parts for ageing equipment or discontinued products—known as legacy parts. When manufacturers stop supplying these components, organisations rely on reverse engineering to produce compatible substitutes, ensuring seamless integration and continued operability.

Another reason comes from the desire to improve existing designs; analysing and updating products for increased efficiency, reliability, and overall performance. Lastly, gaining insight into original manufacturing techniques enables engineers to maintain continuity during restoration projects or emulate sought-after characteristics found within legacy parts. Overall, reverse engineering serves as a versatile solution for addressing complex demands across multiple industries, fostering creativity, resilience, and progression in manufacturing practices.

The Reverse Engineering Process

Reverse engineering involves different techniques to understand how things are made. One common method is laser scanning, which captures detailed measurements of existing parts. This information is then used to create 3D drawings and models using computer-aided design (CAD) software. Another technique is rapid prototyping, where a quick pattern is made to test the design before making the final part.

When reproducing classic parts, it is important to balance quality and authenticity. This means making sure the new part looks and works like the original, while also meeting modern standards. By using these techniques, engineers can recreate old parts accurately and efficiently, helping to keep important machinery and equipment running smoothly. Reverse engineering is a valuable process that allows us to learn from the past and make improvements for the future.

Advantages and Challenges of Reverse Engineering

Advantages:

Reverse engineering allows for the reproduction of existing parts or products with improved quality. This is because it enables engineers to analyse a product’s design, material, and construction thoroughly. Through this analysis, they can identify any weaknesses or areas that require improvement, allowing them to create an enhanced version of the original part.

Additionally, reverse engineering provides flexibility when it comes to adapting to modern manufacturing techniques. By understanding how a product was originally designed, engineers can modify it to take advantage of new technologies, tools, or processes. This results in more efficient production methods, reduced costs, and higher-quality output.

Challenges:

One major challenge faced during reverse engineering is balancing authenticity with functionality. Preserving the exact look, feel, and performance of the original part while improving its overall quality can be difficult. Engineers must carefully consider each aspect of the design and weigh the importance of maintaining authenticity against the benefits of making improvements.

Another significant challenge is ensuring compatibility with original parts. When modifying a component, there’s always a risk that it may not work well with other components within the system. Compatibility issues could lead to malfunctions, decreased efficiency, or even complete failure. Therefore, extensive testing and validation are necessary throughout the reverse engineering process to ensure seamless integration with existing systems.

Applications and Future Prospects

Reverse engineering has diverse applications across numerous industries such as automotive, aerospace, medical devices, electronics, software, and heavy machinery. It plays a crucial role in repairing legacy equipment, recreating obsolete components, upgrading outdated designs, and creating interoperable solutions. The potential for future advancements in reverse engineering technology remains vast. With innovations like artificial intelligence (AI), machine learning (ML), and advanced imaging techniques, reverse engineering processes will become faster, more accurate, and cost-effective.

Reverse engineering has diverse applications across numerous industries such as automotive, aerospace, medical devices, electronics, software, and heavy machinery. It plays a crucial role in repairing legacy equipment, recreating obsolete components, upgrading outdated designs, and creating interoperable solutions. The potential for future advancements in reverse engineering technology remains vast. With innovations like artificial intelligence (AI), machine learning (ML), and advanced imaging techniques, reverse engineering processes will become faster, more accurate, and cost-effective.

These technological breakthroughs have the potential to revolutionise fields like digital twin creation, virtual prototyping, and predictive maintenance. Moreover, reverse engineering significantly impacts innovation and product development by enabling businesses to leverage their competitors’ strengths, address market gaps, and develop unique solutions tailored to customer needs. Thus, reverse engineering continues to play a vital role in driving industrial growth and competitiveness.

To summarise, reverse engineering holds immense value in today’s fast-paced and ever-evolving business landscape. Its ability to recreate, adapt, improve, and innovate makes it a powerful tool for organisations operating across various sectors. Companies seeking to enhance their operations, reduce costs, extend the life cycle of their assets, and maintain a competitive edge should strongly consider incorporating reverse engineering methodologies into their strategies. At Thompson Precision, we remain steadfastly committed to delivering unparalleled precision and accuracy through our customised reverse engineering services.