Thompson Precision Engineering is a leading provider of high-precision CNC machining services, specialising in rapid prototyping, product development, and full-scale production. Finding a reliable machining partner is crucial for ensuring timely delivery and exceptional results. Thompson Precision Engineering stands out from the competition with the extensive range of services, including precise engineering, fast turnaround times, large milling capabilities, mechanical design expertise, reverse engineering and more. By choosing Thompson Precision Engineering, clients can benefit from end-to-end services, streamlining their manufacturing process and reducing time to market.

High Precision CNC Machining

High-precision CNC machining refers to the use of computer numerical control (CNC) machines to produce parts with extremely tight tolerances and high accuracy. This process utilises advanced technology and specialised tools to achieve precision measurements and surface finishes that are not possible with traditional manufacturing methods. High-precision CNC machining is used in various industries such as aerospace, where parts must meet strict safety and performance standards, and medical, where components must be precise enough to fit within the human body. Other industries that require high-precision CNC machining include automotive, defence, and electronics. The ability to produce complex shapes and designs with exacting precision has made high-precision CNC machining an essential part of modern manufacturing.

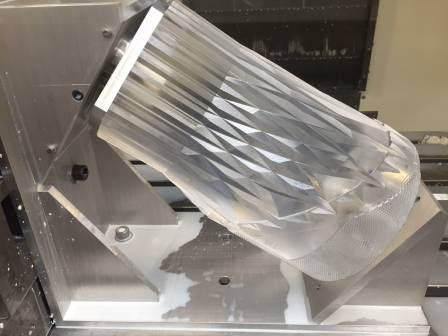

Large CNC Milling

This process uses rotating cutting tools to shape and size the workpiece and can produce large parts and components with high accuracy and surface finish. Large CNC milling machines have a large bed or table that can accommodate large workpieces, allowing for the production of parts that are too big to be produced on smaller machines. These machines typically have powerful spindles and advanced controls that enable them to perform complex operations quickly and accurately. In the aerospace industry, large CNC milling machines are used to produce wing structures, fuselage components, and engine parts. In the marine industry, they are used to create boat hulls and deck components. Heavy machinery manufacturers also rely on large CNC milling machines to produce components such as engine blocks, cylinder heads, and gearbox housings.

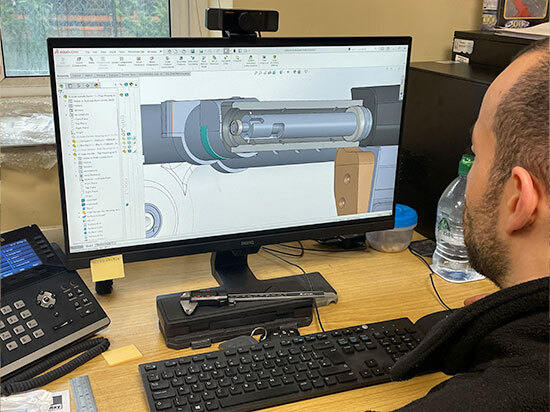

Mechanical Design

Mechanical design is the process of creating and optimising the physical properties of a device or system, such as its shape, size, materials, and movement. It involves the application of principles from mechanics, engineering, and physics to create functional and efficient systems. Mechanical design is used in a wide range of industries, including robotics, aerospace, automotive, and consumer products. For example, when designing a new product, mechanical engineers will consider factors such as durability, weight, and cost to create a product that meets the desired specifications. They may also redesign existing products to improve their performance, reduce maintenance requirements, or lower production costs.

Mechanical design is the process of creating and optimising the physical properties of a device or system, such as its shape, size, materials, and movement. It involves the application of principles from mechanics, engineering, and physics to create functional and efficient systems. Mechanical design is used in a wide range of industries, including robotics, aerospace, automotive, and consumer products. For example, when designing a new product, mechanical engineers will consider factors such as durability, weight, and cost to create a product that meets the desired specifications. They may also redesign existing products to improve their performance, reduce maintenance requirements, or lower production costs.

Rapid Prototyping

The benefits of rapid prototyping include significant time and cost savings, as well as the ability to iterate and improve designs quickly. Traditional prototyping methods can be slow and expensive, requiring weeks or even months to produce a single prototype. Rapid prototyping, on the other hand, allows for the creation of multiple prototypes in a matter of days or hours, enabling designers to test and refine their ideas more quickly. Additionally, rapid prototyping allows for more accurate testing and validation of designs, reducing the risk of errors and defects in the final product. Overall, rapid prototyping enables a more efficient and effective design process, ultimately leading to better products and increased customer satisfaction.

Engineering Consultancy

Engineering consultancy refers to the provision of expert advice and guidance by experienced engineers to help clients solve technical problems, optimise designs, and improve manufacturing processes. Engineering consultants can provide valuable insights and recommendations to clients across a variety of industries, including manufacturing, construction, and energy. Engineering consultancy is particularly useful in situations where clients require objective, third-party expertise to address specific technical challenges. For example, during the design phase of a project, engineering consultants can help optimise designs for manufacturability, efficiency, and cost-effectiveness. They can also assess the feasibility of proposed designs, identify potential issues, and suggest improvements.

Reverse Engineering

Reverse engineering is the process of analysing and understanding the design and functionality of an existing product, system, or software, usually to duplicate or modify it. This process involves taking apart the product or system, examining its components, and analysing its design, architecture, and performance. Reverse engineering is used in various fields such as electronics, mechanical engineering, software development, and biotechnology. Reverse engineering is necessary in situations where there is a lack of documentation or information about a product or system, or when a product or system needs to be improved or modified. For instance, when a company wants to reproduce a legacy part that is no longer available, reverse engineering can be used to understand the original design and create a replica.

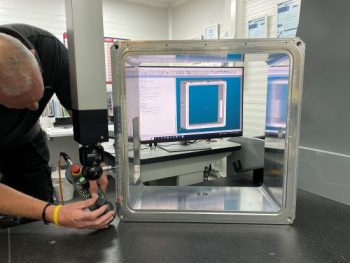

Plastic CNC Machining

Plastic CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to create custom parts and components from plastic materials. The process involves programming the machine with a computer-aided design (CAD) file, which dictates the precise movements of the machine’s cutting tools to shape and cut the plastic material.

Plastic CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to create custom parts and components from plastic materials. The process involves programming the machine with a computer-aided design (CAD) file, which dictates the precise movements of the machine’s cutting tools to shape and cut the plastic material.

Examples of projects that require plastic CNC machining include:

- Custom parts for industrial equipment

- Enclosures for electronic devices

- Medical implants and instruments

- Aerospace components

- Automotive parts and prototypes

- Robotic components

- 3D printing parts

Plastic CNC machining offers several advantages over other manufacturing processes, including fast turnaround times, high precision, and low tooling costs. It also allows for the production of complex geometries and intricate details, making it a versatile solution for a wide range of applications.

Thompson Precision Engineering provides end-to-end solutions for CNC machining projects, including design, engineering, manufacturing, and finishing. We have cutting-edge technology and skilled staff, giving top priority to precision and timeliness. Our dedication to quality and ability to fulfil tight deadlines make us an excellent choice for businesses looking for a dependable partner for their CNC machining requirements. Visit our website or get in touch to find out more about our skills and how we can assist in bringing your concepts to life.