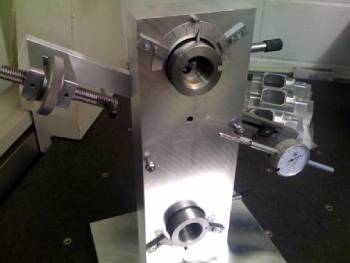

High Precision Jig for Chinook Composite Armoured Aircrew Seats

Thompson Precision manufacture complex parts from a wide range of materials for many companies working in the Aerospace Industry. Using 3 and 5 Axis CNC Machining, we can make challenging components quickly and accurately, and can provide full traceability and First Article Inspection Reports if required.

We regularly machine a wide range of Aerospace-specific metal grades and hold a selection of these in stock for fast-turnaround parts.

With over 20 CNC Machines and multi-skilled precision engineers, we have the tools and the expertise for almost any machining project.

Types of High Precision CNC Machining

We specialise in low-volume, high-precision machining of parts including bespoke testing fixtures and assembly jigs, complex 5 Axis parts machined from solid materials and other difficult projects.

We offer a one-stop machining service, allowing designers and R&D engineers in the Aerospace industry to streamline their procurement – we can source material, machine the part and perform any additional processes you require including painting, plating, polishing and much more.

Most importantly we understand the importance placed on utmost quality and delivery promises in the aerospace world. We are committed to providing a first-class CNC machining service for all areas of aircraft production, maintenance, testing and product development.

Whilst we have produced parts and assemblies for a wide range of aerospace disciplines, we specialise in the production of aerospace special fasteners and test fixtures/assembly jigs.

Aerospace Special Fasteners

Low volume bespoke production of aircraft fasteners from difficult to find materials is a frequent service required by our clients. We are expert in locating and purchasing special aerospace specific materials from around the world to service the requirements of aircraft maintenance organisations. As the aircraft undergoing maintenance get older the more challenging this process becomes. Where we are unable to locate out of production materials, we can offer the nearest available alternative and liaise with the appropriate authorities to secure approval. Most of the work we undertake requires a high degree of problem solving to overcome these kinds of difficulties which are specific to the aerospace industry. Rest assured we will always do our utmost to realise your project quickly and efficiently.

Aerospace Test Fixtures/Assembly Jigs

Aerospace test gauge

We are often asked to support manufacturers in the aircraft industry supply chain with the production of component test fixtures, special gauges and assembly jigs. High precision CNC machining is employed alongside metal and plastic fabrication, assembly, 3D printing and testing. We are also able to offer our 3D CAD design service. Using our SolidWorks software, we can offer rapid assessments of initial designs and continued design development assistance. We can also offer a full design service enabling Thompson Precision to deliver a concept to manufactured product service all under 1 roof and at speed.

To find out how we can help with your next project, contact us by calling 01277 365500 or email [email protected].