Thompson Precision are set up to produce complex parts with an ultra-high level of precision. We offer this service for both small and large components, which are produced through CNC milling and CNC turning in a wide range of metals and plastics.

Thompson Precision are set up to produce complex parts with an ultra-high level of precision. We offer this service for both small and large components, which are produced through CNC milling and CNC turning in a wide range of metals and plastics.

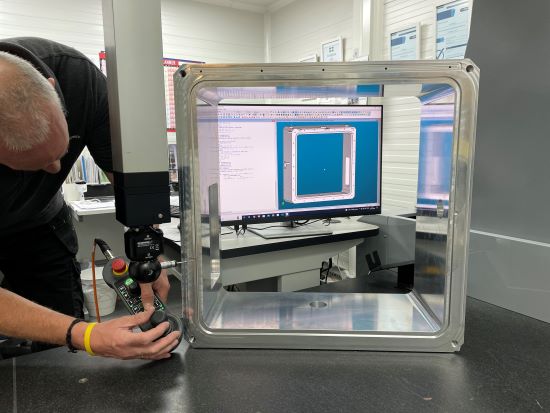

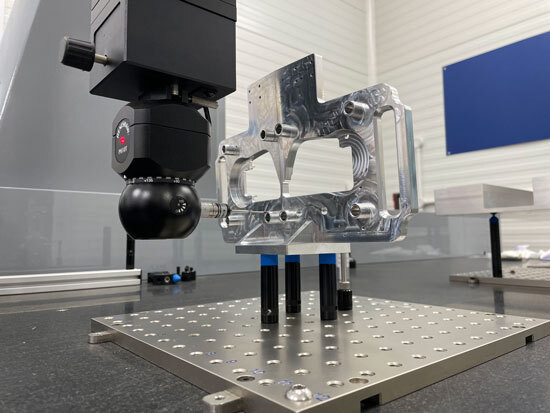

We place a great emphasis on maintaining the highest levels of quality and precision. We have a temperature-controlled Inspection Department that is equipped with a brand-new large format Hexagon Metrology Status CMM (CNC Co-ordinate Measuring Machine), running PC-DMIS software. This machine allows us to maintain and warrant the highest levels of quality and precision. We are able to offer fully automatic checking and reporting, as well as F.A.I.R’s (First Article Inspection Reports) in any format required for components up to 1600 mm x 900 mm x 800 mm.

Balancing Speed and High Precision CNC Machining

We recognise the importance of speed, particularly during the prototype and development phases of a project. We strive to balance the need for fast turnaround with utmost quality to deliver the best possible overall service for their clients. This approach helps to ensure that our clients receive the highest quality products within the shortest possible time frame.

We recognise the importance of speed, particularly during the prototype and development phases of a project. We strive to balance the need for fast turnaround with utmost quality to deliver the best possible overall service for their clients. This approach helps to ensure that our clients receive the highest quality products within the shortest possible time frame.

Thompson Precision’s quality procedures are to the ISO 9001 standard, which we have held since 1990. We also meet the quality standards of several major defence, aerospace, and scientific manufacturers. This demonstrates our commitment to providing top-quality services to our clients.

From Prototyping to Production

Our Approach to High Precision CNC Machining Services

Thompson Precision offers a range of services to meet the needs of our clients, including working with Research and Development teams to machine small batches of components for prototyping. Our Fast CNC Turnaround service is perfect for companies testing and improving complex components with a deadline. This means that clients can rely on Thompson Precision to provide them with the necessary components for their prototyping needs within a short time frame.

Thompson Precision offers a range of services to meet the needs of our clients, including working with Research and Development teams to machine small batches of components for prototyping. Our Fast CNC Turnaround service is perfect for companies testing and improving complex components with a deadline. This means that clients can rely on Thompson Precision to provide them with the necessary components for their prototyping needs within a short time frame.

In addition, Thompson Precision offers a Mechanical Design Service that can help to solve problems with components and make CNC Machined parts more cost-effective. This service is ideal for clients who may have encountered challenges in the design or manufacturing process of their components. Thompson Precision’s experienced engineers can work with clients from the first prototype stage all the way to large-scale production. This helps ensure that the final product meets all the required specifications and is cost-effective to produce.

Thompson Precision’s CNC Machining facilities include large and small 3 Axis and 5 Axis Machines, CNC Lathes, and more. This means that we have the capability to produce components of different sizes and complexities. We also have close connections with a wide range of subcontractors around the country to facilitate electro plating, heat treatment and painting E.T.C. This allows us to tailor production methods to best suit our clients’ components.

Thompson Precision offers a comprehensive range of services that cater to the needs of our clients. From prototyping to production, our commitment to quality, precision, and speed in delivering our services ensures that our clients receive the highest quality products within the shortest possible time frame.