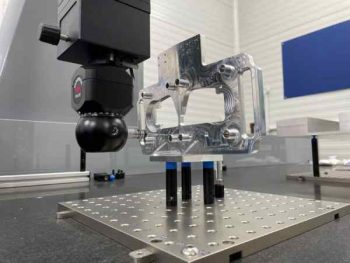

5 Axis CNC Machining is a computer numerical controlled (CNC) machining process that uses five axes to remove material from a workpiece. The five axes include three linear axes (x, y, and z) and two rotary axes (a and b), which allow the cutting tool to move freely in a 3D space. This versatile process enables the creation of complex shapes and designs with unparalleled precision and efficiency. By leveraging this technology, businesses can produce high-quality products quickly and cost-effectively, giving them a competitive edge in today’s fast-paced marketplace.

The Creation of 5-Axis CNC Machining

The advent of 5-axis CNC machining represents a significant milestone in the evolution of manufacturing technology. For decades, traditional machining methods had been the standard for producing large components, but these techniques were limited in their ability to create complex, intricate parts. With the emergence of 5-axis CNC machining, however, manufacturers gained the capability to produce low-volume, high-precision parts with unprecedented speed and accuracy.

The development of 5-axis CNC machining was driven by the need for more sophisticated manufacturing processes. As industries such as aerospace, automotive, and medical device manufacturing became increasingly reliant on complex components, traditional machining methods proved unable to keep pace with demand. To address this challenge, machine tool builders and software developers collaborated to create a new generation of CNC machines capable of executing multiple axes of motion simultaneously.

How Does 5 Axis CNC Machining Work?

At its core, 5-axis CNC machining involves the coordinated movement of five axes (X, Y, Z, A, and B) to create complex shapes and designs. The X, Y, and Z axes represent the three linear dimensions, while the A and B axes represent the two rotational dimensions. The cutting tool moves along each axis, controlled by computer numerical code, to remove material from the workpiece.

At its core, 5-axis CNC machining involves the coordinated movement of five axes (X, Y, Z, A, and B) to create complex shapes and designs. The X, Y, and Z axes represent the three linear dimensions, while the A and B axes represent the two rotational dimensions. The cutting tool moves along each axis, controlled by computer numerical code, to remove material from the workpiece.

During the machining process, the cutting tool moves along the X, Y, and Z axes to position itself at the desired location. Simultaneously, the workpiece is rotated along the A and B axes to present the cutting tool with the appropriate angle and orientation. This synchronised movement of all five axes allows for the efficient creation of complex geometries, including curves, angles, and contours.

The cutting tool used in 5-axis CNC machining can be either a milling cutter or a drill bit. The milling cutter is typically used for removing larger amounts of material, while the drill bit is used for making precise holes. The tool is attached to a spindle, which is responsible for its rotation and movement along the various axes.

Benefits of 5-Axis CNC Machining

A benefit of 5-axis CNC machining is increased efficiency. Setup times are significantly reduced, as the machine can move along all five axes simultaneously, eliminating the need for multiple setups and repositioning of the workpiece. This streamlined process also helps to eliminate errors, resulting in a more reliable and consistent output.

The greater design flexibility offered by 5-axis CNC machining is another significant advantage. The ability to manipulate the workpiece along multiple axes enables the creation of complex shapes and geometries that would be difficult or impossible to achieve using other machining techniques. This makes it an excellent choice for prototyping and production of custom parts with unique features.

Finally, 5-axis CNC machining is often more cost-effective than other machining techniques, particularly for producing low-volume, high-precision parts. The reduction in setup times and elimination of errors mentioned earlier help to minimise production costs, making it a more affordable option for businesses that require small batches of custom parts. Overall, the benefits of 5-axis CNC machining make it an excellent choice for a wide range of industrial applications.

Applications of 5-Axis CNC Machining

One of the primary industries that utilise 5-axis CNC machining is the aerospace industry, where it is used to manufacture aircraft parts such as engine components, control surfaces, and structural elements. The military industry also employs 5-axis CNC machining to produce weapon systems, vehicle parts, and other defence-related components.

One of the primary industries that utilise 5-axis CNC machining is the aerospace industry, where it is used to manufacture aircraft parts such as engine components, control surfaces, and structural elements. The military industry also employs 5-axis CNC machining to produce weapon systems, vehicle parts, and other defence-related components.

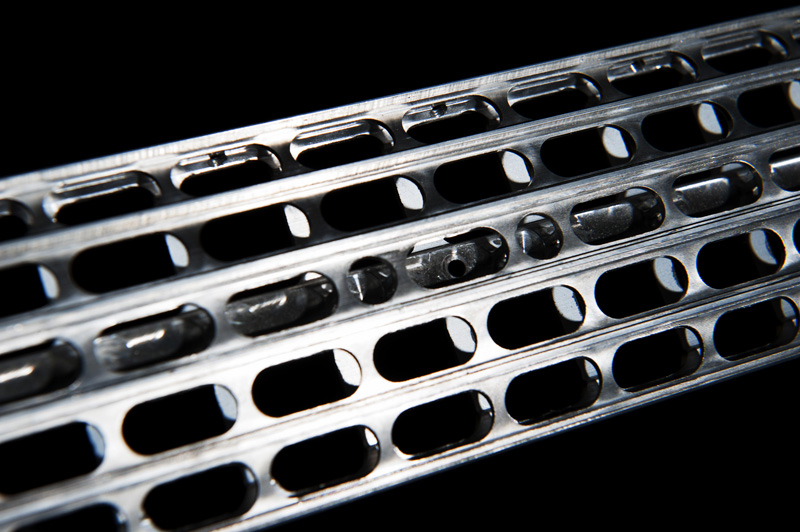

The motorsports industry is another significant user of 5-axis CNC machining, where it is used to fabricate car chassis, engine components, and other racing parts that require high strength and durability. In the medical industry, 5-axis CNC machining is used to produce surgical instruments, implants, and other medical devices that demand strict tolerances and precision.

Other industries that benefit from 5-axis CNC machining include automotive, energy, and industrial equipment manufacturing. In these industries, 5-axis CNC machining is used to produce parts such as engine blocks, cylinder heads, gearboxes, and pumps, among others. Additionally, 5-axis CNC machining is also used in the production of high-performance sports equipment, such as bicycle frames, golf clubs, and tennis rackets.

Comparison with Other Machining Techniques

5-axis CNC machining stands out from other machining techniques, particularly 3-axis machining centres, in terms of its capabilities and advantages. While 3-axis machining centres are limited to cutting along three linear axes, 5-axis machining centres offer additional freedom of motion, allowing for the cutting tool to move along two additional axes, providing greater flexibility and versatility.

Compared to other manufacturing methods such as casting or moulding, 5-axis CNC machining offers several advantages. For instance, casting and moulding processes often require expensive tooling and moulds and may result in parts with less precise dimensions and lower surface finish quality. In contrast, 5-axis CNC machining allows for the production of parts with high levels of accuracy and surface finish, without the need for expensive tooling or moulds.

Moreover, 5-axis CNC machining provides greater design flexibility, enabling the production of complex parts with intricate geometries that would be challenging or impossible to create using other manufacturing methods. Additionally, 5-axis machining centres can be equipped with advanced software and programming tools, enabling efficient and accurate production of parts with minimal material waste and maximum productivity.

Frequently Asked Questions (FAQs)

Can 5-axis CNC machining be used for both metal and non-metal materials?

Yes, 5-axis CNC machining can be used for a wide range of materials, including metals, plastics, composites, and ceramics. However, the specific machining strategies and tools used may vary depending on the material being worked with. For example, cutting tools designed for use on metals may not be suitable for use on plastics or composites, and vice versa.

What are some tips for optimising 5-axis CNC machining performance?

To optimise 5-axis CNC machining performance, it is important to carefully plan and program the machining operation, taking into account the specific requirements of the job and the capabilities of the machine. This includes selecting the appropriate cutting tools, setting up the machine properly, and ensuring proper coolant flow. Additionally, regular maintenance and calibration of the machine can help ensure optimal performance. Finally, investing in training and education for operators and programmers can also help improve overall efficiency and accuracy.

Is 5-axis CNC machining more expensive than other machining methods?

The cost of 5-axis CNC machining can vary depending on factors such as the complexity of the part, the material being used, and the size of the run. However, in many cases, 5-axis CNC machining can actually be more cost-effective than other machining methods due to its ability to reduce setup times and improve part accuracy.

5 Axis CNC Machining has revolutionised the manufacturing industry by offering unparalleled precision, speed, and versatility. Its benefits, including reduced setup times, faster cycle times, improved part accuracy, and increased versatility, have transformed the way companies approach manufacturing. With its ability to produce complex parts with ease, 5 Axis CNC Machining has opened up new possibilities for innovation and creativity in product design. As technology continues to advance, the potential for 5-axis CNC Machining to drive innovative manufacturing solutions is vast and exciting. With the right equipment, software, and trained professionals, manufacturers can leverage this technology to stay ahead of the competition and meet the evolving demands of their customers.