London Underground, having depleted their stock of a vital train steering component, found that they could no longer purchase the spare part from the manufacturer. In addition the drawings and material specifications were not available so they came to us. All we were provided was an unworn original part that we were required to copy and re-produce.

London Underground, having depleted their stock of a vital train steering component, found that they could no longer purchase the spare part from the manufacturer. In addition the drawings and material specifications were not available so they came to us. All we were provided was an unworn original part that we were required to copy and re-produce.

Our first part of this job was to carry out tests to ascertain the correct material which showed us to be a casting grade of aluminium.

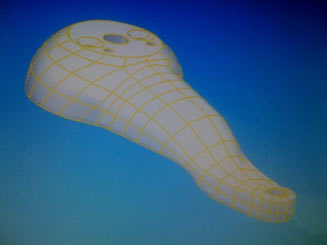

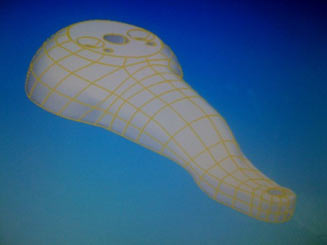

Laser Scanning Equipment Used

We then used laser scanning equipment to scan the part into a 3D CAD format from which we could generate a CNC machining program. With only a low volume of parts required it was more economical to CNC machine the parts from solid material. We also took the opportunity to upgrade the material to aerospace grade aluminium as it was reported that the original 1970’s manufactured parts were breaking into 2 pieces rather than just wearing out.

We then used laser scanning equipment to scan the part into a 3D CAD format from which we could generate a CNC machining program. With only a low volume of parts required it was more economical to CNC machine the parts from solid material. We also took the opportunity to upgrade the material to aerospace grade aluminium as it was reported that the original 1970’s manufactured parts were breaking into 2 pieces rather than just wearing out.

The client, London Underground were more than happy with the results and have saved themselves a lot of money by utilising our team of experienced engineers to reproduce this part for them.

This is just an example of some of the many projects we have undertaken. If you would like to find out more then please feel free to contact us and we will help you with your requirements. No job is too big or too small for our team who have experience in all sorts of requirements. We thrive on challenges!