Any company or individual involved in any way with the manufacturing industry will tell you that being both cost efficient and time efficient is absolutely crucial. It’s for that reason that anything which can save both time and money should be readily seized upon by any organisation interested in being successful.

Precision engineering is the expert designing and creation of components, machinery, equipment and systems using the most up to date and sophisticated techniques and technology available. As such, using a precision engineering company is exactly the kind of thing which can save both time and money, and can do so in a number of different ways.

Top 5 Ways Precision Engineering Saves Time and Money

By Eliminating Human Error

Precision engineered machinery and tools are advanced numerically controlled machines which often require far less human supervision and control. As such, the manufactured goods which they produce are less subject to human error, as the machines are designed and built specifically for precision.

What that means is that the potential costs, both in terms of finance and of time, related to correcting such errors is greatly reduced. This, therefore, is a key benefit of utilising a precision engineering company.

By Speeding Up Production

Being able to offer your customers and clients reliably fast turnaround times is absolutely crucial for any company. Precision engineering, by definition, involves the creation of perfect components and products each and every time.

What that means is that precision engineered machines are faster than those controlled by human beings and what they produce – as mentioned above – is free of errors. Faster production and guaranteed quality, therefore, allows any company to ensure shorter turnaround times.

By Reducing Wastage

Precision engineering as a field is dedicated to achieving the most efficient production possible in terms of materials as well as of time. Using a precision engineering company, therefore, can help you to reduce the wastage involved in the manufacturing process.

This can lead to significant savings in any industry but is particularly important for any company which utilises expensive raw materials. Even a comparatively small reduction in wastage for those companies, after all, can translate to huge reductions in costs.

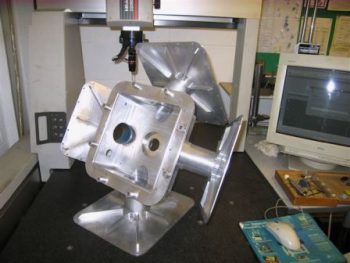

By Producing Specialised, Complex Parts

You might be surprised at just how much more efficient any production process could be made by the introduction of just one specialised and precision engineered component. All manner of manufacturing machinery could be improved by the replacement of certain parts with better tailored components, and such complex parts can only be produced through precision engineering.

Using the services of a precision engineering company, therefore, to produce such a component could have a profound impact on both time and cost efficiency over the longer term.

By Offering an All-in-One Service

Most good precision engineering companies are such specialists in their field that they can fulfil the specific requirements of a company or organisation from start to finish. What we mean by this is that they can provide designs for manufacture, machining and assembly of any parts and components as one all-in-one service.

As a result, whatever the part, component or machine required once its creation has been trusted to a precision engineering company there will be no further costs in terms of finances or time for the company’s client.