Precision engineering is an essential component of the aerospace and defence industry. Aerospace and defence technologies require incredibly precise and reliable components to ensure safe and efficient operations. Precision engineering techniques and technologies have enabled advancements in aviation, space exploration, and defence systems, enhancing our capabilities and pushing the boundaries of what’s possible.

The use of precision engineering in aerospace and defence has been critical to the success of many missions and systems. One example is the use of precision machining techniques in the fabrication of turbine blades and other critical engine components. These components must be made to exacting specifications to ensure maximum efficiency, reliability, and safety. Precision machining allows for incredibly tight tolerances and extremely smooth surface finishes, minimizing wear and tear and extending the life of the component.

Use in Aerospace and Defence Systems

Another example is the use of precision engineering in the development of guidance systems for missiles and other defence systems. These systems must be able to navigate to a target with pinpoint accuracy, and any deviation from the intended trajectory could result in catastrophic consequences. Precision engineering techniques, such as GPS technology and advanced sensors, enable these systems to achieve unprecedented levels of accuracy and reliability.

Precision engineering is also used in the development of satellites and other spacecraft. These complex systems require components that can withstand the extreme temperatures and harsh conditions of space. Precision machining and other manufacturing techniques enable the production of components that are not only incredibly precise but also durable and resistant to extreme environmental conditions.

Advancement in Precision Engineering Technology

The advancement of precision engineering in the aerospace and defence industries has also led to new opportunities for innovation and growth. For example, advancements in materials science, such as the development of lightweight composite materials, have allowed for the production of more fuel-efficient and environmentally friendly aircraft. Similarly, the use of unmanned aerial vehicles (UAVs) and other autonomous systems has opened up new possibilities for exploration and data collection.

Why Thompson Precision?

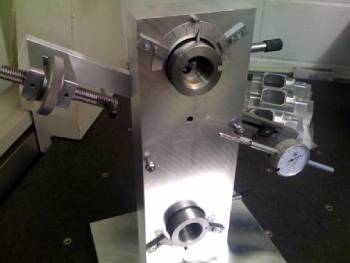

Thompson Precision manufacture complex parts using a variety of materials for the Aerospace Industry. Our advanced 3 and 5 Axis CNC Machining capabilities allow us to produce challenging components with precision and efficiency. We are committed to providing full traceability and First Article Inspection Reports as necessary to ensure the highest quality standards.

Our extensive experience in machining a broad range of Aerospace-specific metal grades enables us to deliver fast turnaround times and optimal results. We maintain a stock of these materials to ensure we can quickly respond to our clients’ needs.

Our Precision Engineering Advantage

With over 20 state-of-the-art CNC machines and a team of highly skilled precision engineers, we have the resources and expertise to handle almost any machining project. Our team is committed to delivering exceptional quality, fast turnaround, and excellent customer service to meet our clients’ unique needs.

Whether you require a custom-designed component or a high-volume production run, our team can provide the solutions you need to succeed in the Aerospace Industry. Trust Thompson Precision to deliver the precision engineering solutions you need to stay ahead of the competition.

Our one-stop machining service is designed to streamline the procurement process for designers and R&D engineers in the Aerospace industry. We can source materials, machine parts, and perform any additional processes required, such as painting, plating, polishing, and more.

Quality and on-time delivery are of utmost importance in the Aerospace industry, and we take pride in delivering a first-class CNC machining service for all areas of aircraft production, maintenance, testing, and product development. While we have experience producing parts and assemblies for various aerospace disciplines, we specialize in the production of aerospace special fasteners and test fixtures/assembly jigs.

Expertise and Aerospace Parts and Materials

Our expertise in locating and purchasing special aerospace-specific materials from around the world enables us to provide low-volume bespoke production of aircraft fasteners from hard-to-find materials. We understand the challenges that come with locating out-of-production materials and offer the nearest available alternatives while liaising with the appropriate authorities to secure approval. Our team is equipped to handle challenging problems specific to the aerospace industry, ensuring your project is realised quickly and efficiently.

At our Thompson Precision, we are committed to providing exceptional quality and customer service, ensuring our clients’ projects are completed on time and to the highest standards. Trust us to provide the precision engineering solutions you need to succeed in the Aerospace industry.