The Solution

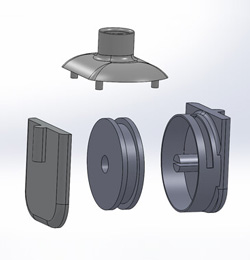

The first stage was to understand the client’s exact requirements and specifications for the product. From here our design team could get started on developing several concepts that would meet these requirements. A final concept was then established from merging the best parts from each initial concept. This was then converted into a 3D model within SolidWorks, our 3D CAD software. This allowed our client to see a visual representation of their design produced in SolidWorks, giving them the chance to modify any areas of the design. It also allowed our client to work alongside our design engineers to make sure their visual and functional needs for the product are completely met.

The first stage was to understand the client’s exact requirements and specifications for the product. From here our design team could get started on developing several concepts that would meet these requirements. A final concept was then established from merging the best parts from each initial concept. This was then converted into a 3D model within SolidWorks, our 3D CAD software. This allowed our client to see a visual representation of their design produced in SolidWorks, giving them the chance to modify any areas of the design. It also allowed our client to work alongside our design engineers to make sure their visual and functional needs for the product are completely met.

Prototype Meets Clients Specifications

Once the final concept was decided with the client, a prototype was produced. This was done using SLA Rapid Prototyping for some of the more complex parts, with other components being machined from aluminium and a custom made spring produced. The parts were then assembled and extensively tested to ensure the prototype meets the client’s specification. Once the client was happy with the prototype, the next stage of the project was to start modifying the design for production. With most of the parts being injection moulded, our design engineers altered the CAD data by adding draft angles on the required areas; this meant the components would be easier to remove from the mould,and would make the manufacturing process as smooth and easy as possible.

Once the final concept was decided with the client, a prototype was produced. This was done using SLA Rapid Prototyping for some of the more complex parts, with other components being machined from aluminium and a custom made spring produced. The parts were then assembled and extensively tested to ensure the prototype meets the client’s specification. Once the client was happy with the prototype, the next stage of the project was to start modifying the design for production. With most of the parts being injection moulded, our design engineers altered the CAD data by adding draft angles on the required areas; this meant the components would be easier to remove from the mould,and would make the manufacturing process as smooth and easy as possible.

The client was extremely pleased with our design and manufacture of their prototype. The prototyping process is important to clients as a way to further investigate the viability of their product on the market.