Gearbox failures strike one in every 145 wind turbines annually, costing operators millions in downtime. What if superior machining could extend shaft life beyond the typical 20-year target? In the world of renewable energy, reliability is everything, and Thompson Precision stands at the forefront, delivering precision engineering solutions that enhance the durability of wind turbine gearbox shafts.

Wind turbines play a vital role in powering the green revolution, but their gearboxes endure incredible stresses, torque fluctuations, vibrations, and misalignments that often lead to premature failures. These failures not only disrupt energy production but also drive up maintenance costs and operational downtime. That’s where the expertise of Thompson Precision matters most: crafting gearbox shafts with ultra-precise machining that withstand these harsh conditions and push the boundaries of durability.

With advanced CNC turning, grinding, and surface engineering techniques, Thompson Precision optimises every micron of the shaft’s geometry and finish. This attention to detail minimizes vibrations, combats micropitting, and reinforces bearing integrity, common failure points in turbine gearboxes. Their rigorous testing protocols simulate real-world loads, ensuring shafts are primed for decades of reliable service.

As the demand for sustainable energy grows, so too does the need for gearboxes that operate flawlessly longer. Thompson Precision’s tailored approach to shaft machining is revolutionising wind turbine reliability, helping operators safeguard their investments and stay ahead in the race for net-zero power.

The Hidden Failures in Wind Turbine Gearboxes

Wind turbines harness renewable power, yet their gearboxes crumble under relentless demands. High-speed shafts face torque spikes, rotor imbalances, and environmental assaults, triggering failures that halt operations. Operators grapple with repair bills soaring into millions, underscoring the urgency for robust solutions.

Common issues plague these critical components:

- High failure rate in high-speed shaft bearings due to axial cracking and debris contamination.

- Micropitting from surface fatigue under mixed-film elastohydrodynamic lubrication (EHL), leading to micro-cracks and progressive wear.

- Misalignment causing uneven gear tooth loads and accelerated fatigue life reduction.

- Bearing damage from particles, overload, or poor lubrication, resulting in spalling and seizures.

Industry stats paint a grim picture. Gearboxes rarely reach their 20-23 year design life, with overhauls often required within 10-15 years. Downtime costs exceed £200,000 per incident, amplified in offshore settings. These vulnerabilities stem from Hertzian contact stresses and white etching cracks, demanding intervention.

These failures demand advanced machining to fortify shafts against real-world stresses. Thompson Precision rises to the challenge, deploying precision techniques that transform weak links into enduring assets.

Core Machining Techniques for Shaft Durability

Precision Turning: The Foundation of Strength

The foundation of a durable wind turbine gearbox shaft lies in precision turning, a process that demands meticulous control over material and geometry. Thompson Precision begins with selecting high-alloy steels known for their exceptional fatigue resistance and ability to withstand repeated Hertzian contact stresses. These materials provide the backbone necessary for shafts to endure demanding service conditions.

Next comes multi-axis CNC turning, a critical step that achieves exceptionally tight tolerances often below 5 microns. This precision reduces runout, a measure of shaft misalignment that can dramatically increase vibration and wear. By minimising runout, the shaft maintains balanced rotation, optimising gear mesh and extending bearing life.

Key benefits of precision turning include:

- Enhanced concentricity for smooth torque transmission.

- Reduced vibration, which prevents premature component fatigue.

- Consistent surface finish that supports effective lubrication films.

Grinding Mastery Against Micropitting

Beyond turning, grinding is fundamental in shaping gear shaft profiles to exact dimensions. Profile grinding ensures optimal tooth geometry, helping to prevent common surface defects like frosting and grey staining that can signal early micropitting. Thompson Precision utilises advanced grinding wheels, such as cubic boron nitride (CBN), for precise material removal without overheating the surface.

Additional techniques include:

Superfinishing to improve the lambda ratio, which compares the oil film thickness to surface roughness. A higher ratio means better formation of elastohydrodynamic lubrication (EHL) films, critical to reducing micropitting.

Thorough post-grind inspections with coordinate measuring machines (CMM) to verify perfect gear mesh alignment, crucial for even load distribution.

Heat Treatment and Surface Engineering

To bolster the shaft’s resistance to wear and fatigue, specialized heat treatment and surface engineering are applied. Carburising and nitriding processes produce hardened surface layers while maintaining a tough, ductile core, effectively preventing spalling and crack initiation. Physical Vapor Deposition (PVD) coatings further enhance wear resistance under harsh operating conditions.

These processes focus on:

- Optimising bearing preload to extend component life.

- Mitigating Hertzian contact stresses, the root cause of many surface failures.

- Enhancing corrosion resistance in challenging environments.

By integrating precision turning, expert grinding, and advanced heat treatment, the shafts manufactured by Thompson Precision are engineered to withstand full torque loads and the substantial weights of rotor assemblies. This meticulous approach ensures long-lasting performance and reliability in the harsh environment of wind turbine

Thompson Precision’s Approach: From Design to Delivery

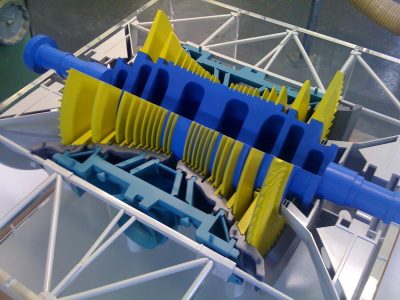

At Thompson Precision, the challenge of manufacturing wind turbine gearbox shafts is met with cutting-edge technology and tailored expertise. Our proprietary 5-axis milling capabilities allow us to produce complex splines and intricate shaft geometries with unparalleled accuracy. This flexibility ensures components meet the demanding specifications required for both planetary and parallel gearboxes.

We incorporate in-line metrology systems throughout the machining process, delivering zero-defect shafts by detecting deviations in real-time. This precision approach reduces the risk of costly rework and guarantees parts are ready for immediate assembly.

To validate durability before deployment, Thompson Precision employs sophisticated testing rigs that simulate real-world load conditions. Our procedures include:

Simulated torque and misalignment loading to replicate operational stresses.

Endurance runs exceeding 10 million cycles to assess fatigue resistance.

We utilise gear mesh deflection analysis techniques to detect subtle changes in gear engagement that could signal developing faults. Additionally, our approach mitigates the risk of white etching cracks, a common cause of shaft failure, by monitoring microstructural integrity throughout testing.

This comprehensive testing regime ensures our shafts can withstand the toughest environments, elevating overall gear system durability. The result is a reduction in operational expenditure (OpEx) for owners, whether offshore or onshore, through fewer failures and longer maintenance intervals. Thompson Precision’s integrated approach from design through testing optimises performance, reliability, and cost-effectiveness for the renewable energy sector.

Future-Proofing: Innovations on the Horizon

Thompson Precision looks ahead, embracing innovations that redefine wind turbine gearbox shaft durability. These advancements address evolving challenges in renewable energy, pushing performance boundaries further.

Emerging trends include:

- AI-optimised tool paths for adaptive machining, adjusting in real-time to material variations and enhancing surface integrity.

- Additive hybrids combining 3D printing with subtractive processes to create lightweight, durable shafts with superior fatigue resistance.

- Lube-integrated designs that combat foaming and bearing failures by embedding lubrication channels directly into shaft geometry.

These breakthroughs tie directly to sustainability goals. Longer-lasting shafts mean fewer replacements, slashing waste and lowering the carbon footprint of wind farm maintenance. Operators benefit from extended service intervals, aligning with the global push for net-zero emissions. Thompson Precision integrates these technologies to future-proof your turbine investments.

Power Up Your Turbines with Thompson Precision

Gearbox failures strike wind turbines hard, but precision turning, grinding, and rigorous testing hook those vulnerabilities head-on. Thompson Precision delivers gearbox shafts built for durability, tackling axial cracking, micropitting, and misalignment with unmatched expertise. From multi-axis CNC processes achieving sub-5 micron tolerances to superfinishing that boosts EHL performance, our techniques extend component life far beyond industry norms.

Comprehensive testing rigs simulate torque overloads and endurance cycles exceeding 10^7 runs, ensuring zero-defect delivery compliant with IEC 61400 standards. Operators cut downtime by up to 40% and slash OpEx through fewer overhauls.

Contact Thompson Precision today for a free consultation on your wind turbine gearbox needs, visit thompsonprecision.co.uk.

Machining excellence secures the net-zero future, powering reliable renewables for generations ahead. With innovations like AI-optimised paths and sustainable designs, Thompson Precision drives the wind energy revolution forward.

FAQs

What causes most wind turbine gearbox shaft failures?

High-speed bearing cracks and micropitting from misalignment top the list, often due to debris and overloads.

How does precision machining UK improve durability engineering?

Tight tolerances and superfinishing enhance load distribution and elastohydrodynamic lubrication (EHL) films, combating surface fatigue in wind turbine gearbox shafts.

Can Thompson Precision handle large wind turbine gearbox shafts?

Yes, up to 2m diameter with full traceability and CNC expertise for durability engineering.

What’s the typical lead time for precision machining UK projects?

6-8 weeks for prototypes, scalable for production runs of wind turbine gearbox shafts.