Imagine a Formula 1 piston machined to tolerances of just 10-20 microns, thinner than a quarter of a human hair, which measures around 70 microns thick. These ultra-precise components endure 20,000 RPM, where pistons accelerate at over 10,000g, facing extreme heat, pressure, and vibration that demand flawless reliability. One tiny deviation can spell disaster: engine failure mid-race, lost power delivery, poor thermal efficiency, or a DNF that costs championships.

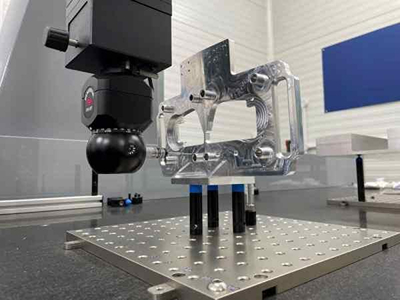

Enter precision CNC machining, the invisible pit crew crafting these power unit heroes from solid billet. At Thompson Precision, we harness 5-axis CNC technology to deliver the repeatability and speed that keep F1 engines on the grid and in the points.

Modern F1 engines rely on advanced 3- and 5-axis CNC machining to sculpt complex combustion chambers, cooling jackets, and hybrid housings from billet stock, achieving strength-to-weight ratios impossible with casting. Teams select high-performance materials like aerospace-grade aluminium alloys (e.g., 7075-T6), titanium for valve trains, and engineering plastics for MGU casings to optimise thermal management and reduce mass.

Thompson Precision brings decades of proven expertise, with 3/4/5-axis CNC capacity, rapid prototyping, and a track record in high-stakes precision engineering for UK motorsport teams. This guide serves as your step-by-step roadmap to specifying, designing, and sourcing CNC-machined F1 engine components, like pistons, crankcases, and turbo housings, that hit tolerances right the first time and arrive on schedule for dyno testing or race weekends.

Typical F1 Engine Components Machined by CNC

Precision CNC machining forms the backbone of Formula 1 power units, turning billet stock into lightweight, high-strength parts that withstand 20,000 RPM and extreme thermal loads. Here are key components where 3- and 5-axis CNC excels, enabling complex geometries, rapid prototyping for dyno validation, and rigorous inspection for zero-defect reliability.

Cylinder heads and combustion chambers: 5-axis CNC machines intricate port shapes, valve seats, and cooling passages in a single setup, optimising airflow and heat dissipation while rapid prototyping speeds design iterations and CMM inspection verifies micron-level sealing faces.

Engine blocks, crankcases, and sumps: High-precision 3- and 5-axis milling bores main bearing caps and oil galleries with tolerances under 0.0025mm, where billet machining avoids casting weaknesses, quick-turn prototypes support engine builds, and in-process gauging ensures alignment.

Pistons, connecting rods, pins, and valve train parts (valve retainers, buckets, rocker components): CNC turning and 5-axis milling achieve 10-20 micron pin bores and skirt profiles on pistons, with titanium rods machined for fatigue resistance; prototyping refines weight distribution, and crack detection plus DLC coating inspection guarantee durability.

Turbocharger housings, compressor wheels, and MGU housings: 5-axis CNC crafts curved impeller blades and thin-walled housings from nickel alloys or titanium, reducing weight and turbo lag; fast prototypes test hybrid integration, while NDT and balancing checks prevent failures under boost.

Cooling manifolds, oil galleries, pump bodies, and complex brackets: Multi-axis machining drills precise cross-channels and contours fluid paths for optimal flow, using engineering plastics or alloys; rapid prototyping validates thermal performance, and leak testing plus surface finish checks ensure efficiency.

Choosing the Right Materials and Processes

Material selection drives F1 engine performance, dictating strength under 20,000 RPM, thermal efficiency, and weight savings. CNC machining unlocks these alloys and composites from billet or forging, with processes tailored to motorsport extremes.

Common Materials in F1 Engine CNC Machining

- High-strength aluminium alloys (e.g., 7075-T6) for blocks, heads, and sumps: Offer superior strength-to-weight and thermal conductivity, machined from billet for defect-free structures that shed mass versus castings.

- Titanium alloys for rods, valves, and high-load fasteners: Deliver exceptional fatigue resistance and lightness at elevated temperatures, ideal for 5-axis contouring despite high cutting forces.

- High-grade steels and nickel alloys for crankshafts, pins, and turbo components: Provide durability under boost and shear loads, with CNC grinding ensuring balance and surface integrity.

- Engineering plastics and composite tooling boards for intake components, hybrid housings, and tooling: Enable low-friction, lightweight MGU casings and prototypes, machined rapidly for validation.

Matching Material to CNC Capability

Difficult-to-machine materials like titanium and nickel alloys, plus thin-wall sections on sumps or housings, demand skilled multi-axis machinists, vibration-damping fixtures, and optimised feeds/speeds to avoid tool deflection or heat buildup. Inexperienced setups risk scrapped parts or distorted tolerances under F1’s 10-20 micron demands.

Capable suppliers advise on:

- Material selection balancing machinability, strength, and thermal performance, e.g., aluminium over magnesium for chatter-prone features.

- Stock forms like forgings or near-net shapes to cut cycle time while preserving grain-flow for crankshafts and rods.

Surface Treatments and Coatings

Post-machining elevates F1 components:

- Heat treatment, shot peening, and superfinishing reduce fatigue and friction on pistons and cams.

- Hard anodising and plating combat corrosion and wear in oil galleries and housings.

- Low-friction coatings like DLC on skirts and pins slash drag by microns-thick layers.

- Factor these into CNC from day one, machine oversize for coating buildup, then verify final dimensions via CMM to hit functional specs.

3‑ and 5‑Axis CNC Machining for Complex F1 Geometry

Multi-axis CNC machining turns F1 billet into race-winning power units, with 3-axis handling basics and 5-axis conquering complexity. Thompson Precision deploys both for motorsport precision.

When 3-Axis Machining is Enough

High-precision 3-axis CNC suits straightforward F1 tasks where geometry stays simple. Flat or prismatic components and fixtures: Ideal for engine test rigs or mounting plates needing tight tolerances without curves. Simple flanges, brackets, and covers without undercuts: Perfect for sump covers or intake flanges machined flat in one plane. Advantages include lower cost, simpler CAM programming, and faster setups, key for low-volume spares when 5-axis overkill.

Why 5-Axis CNC is a Game-Changer for F1

5-axis CNC unlocks F1’s demanding geometries in single setups, slashing errors and cycle times.

- Single-setup machining of intricate ports, combustion chambers, and cooling jackets: Machines compound curves on cylinder heads without refixturing.

- Access to tight spaces and compound angles on cylinder heads, turbo housings, and pump bodies: Tilts tools into undercuts and deep pockets effortlessly.

- Superior strength-to-weight optimisation by machining from solid billet whilst avoiding casting defects: Delivers porosity-free parts 20-30% lighter.

This aligns with F1 priorities: reduced weight for lap gains, higher reliability under 20,000 RPM, repeatable performance batch-to-batch, and shorter development loops via rapid iterations.

Programming, Proving Out and Lights-Out Machining

Programming, Proving Out and Lights-Out Machining

The workflow starts with CAM programming using F1 CAD, followed by digital prove-out in simulation software to catch collisions. First-off prove-run on the shop floor verifies tolerances, then stable processes shift to controlled production. Modern 5-axis centres run lights-out or semi-manned for F1’s low-volume batches post-sign-off, boosting lead times by 50% and consistency via closed-loop feedback.

How to Brief a Precision CNC Supplier for F1 Engine Part

Start your enquiry with 3D CAD models in STEP or Solidworks format, accompanied by fully dimensioned 2D drawings that specify GD&T tolerances like ±10 microns for bores and surface finishes of Ra 0.2-0.8µm on bearing journals. Clearly state the material specifications, such as 7075 aluminum or Inconel 718 alloys, along with required heat treatments like T6 tempering and coatings such as DLC for high-wear areas. Include expected operating conditions, detailing peak RPM up to 15,000, temperatures reaching 1,000°C, and dynamic loads from G-forces to inform machining parameters like stress-relief annealing. Finally, outline the quantity for low-volume batches of 30-100 units, firm delivery deadlines, and any premium rush needs like 24-hour prototyping for urgent dyno tests. This complete package aligns with FIA regulations and minimizes quote revisions.

Questions to Ask Your CNC Partner

Ask about the supplier’s direct experience in Formula 1, F2, Formula E, or similar motorsport sectors, requesting case studies on machining engine blocks, pistons, or hybrid housings from billet titanium to prove their handling of racing-specific challenges. Inquire into their 5-axis machining capacity, such as DMG Mori equipment, alongside metrology tools like CMM or Renishaw probes achieving ±5 micron accuracy, and their rapid prototyping services using stocked materials for same-week delivery. Probe typical lead times of 5-7 days for standard runs, availability of premium 24-hour options, and examples of past time-critical projects, like rushing F2 gearbox components that passed scrutineering on schedule. These questions distinguish motorsport experts like Thompson Precision, who provide full inspection reports, from general machinists.

Building a Long-Term Partnership

View precision CNC suppliers as true engineering partners rather than mere machine shops, collaborating on shared R&D for iterative optimizations like refining piston crown geometries through joint CAD simulations and stack-up tolerance analysis to maintain deck heights within 20 microns. Engage in confidential development work under NDAs, exchanging data on material behaviors and fixture designs to accelerate prototypes into production. Long-term partnerships typically slash lead times by 50% through streamlined processes, boost right-first-time rates via shared quality databases, and speed up new engine programs or upgrades, such as turbo impeller tweaks that propel teams toward podium finishes. Thompson Precision fosters these relationships, evolving from initial briefs to reliable production support.

Unlocking Track Success with Precision CNC

Precision CNC machining powers Formula 1 engine components by delivering lightweight, ultra-reliable parts machined to 10-micron tolerances that survive 15,000 RPM and scorching heat cycles, with Thompson Precision’s 5-axis expertise ensuring every piston, block, or turbine blade optimizes power-to-weight ratios for race dominance. Smart Design for Manufacturability alongside titanium and Inconel selections, combined with single-setup 5-axis operations, slashes development cycles while boosting airflow efficiency and durability under G-forces. Rigorous CMM inspections and full traceability confirm components perform from qualifying sprints to 300km race stints without failure, while partnering with motorsport-savvy suppliers like Thompson Precision eliminates risks from late tweaks or spares rushes through 24-hour premiums. F1 teams ready to gain the edge should upload CAD models or parts to thompsonprecision.co.uk now for a free confidential review, book early capacity for engine upgrades via phone or email, and submit enquiries online to transform precision into podium wins.