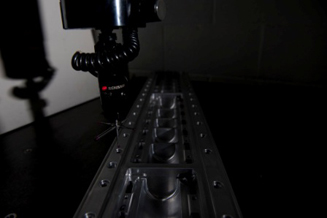

A client approached us to create a heavy-duty electronics enclosure with very specific Radio Frequency requirements, and positional tolerances of 0.025mm over the 1200mm length of the component.

A client approached us to create a heavy-duty electronics enclosure with very specific Radio Frequency requirements, and positional tolerances of 0.025mm over the 1200mm length of the component.

The part was machined from solid aluminium direct from the customer’s 3D CAD data on a 3 axis CNC machining centre using our Delcam Power-mill software. Our engineers set up the CNC machine with the tools needed, and began machining the part.

Challenging Aspect

The main challenge was to maintain the positional tolerances of bored holes over the length of the part. Distortion is always an issue with heavy stock removal so we rough-machined the component all over and allowed it to rest for several days before completing the finish machining. This allowed us to assess whether the part had become distorted.

The main challenge was to maintain the positional tolerances of bored holes over the length of the part. Distortion is always an issue with heavy stock removal so we rough-machined the component all over and allowed it to rest for several days before completing the finish machining. This allowed us to assess whether the part had become distorted.

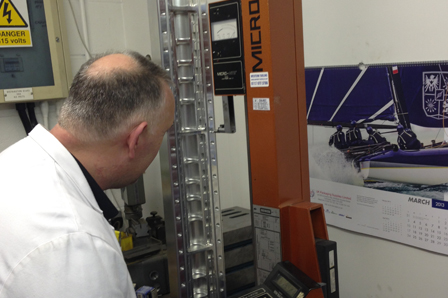

Once machining was complete, our engineers deburred the part and checked all machined areas and tapped holes with highly precise CMM machinery; this ensured the part matched the client’s technical drawing, and remained inside the tolerances set by the client.

Once our Inspection Department checked all bored holes and lengths of the part, as well as ensuring the part hadn’t distorted in manufacturing, the part then had to be anodised. We took responsibility for ensuring the high-quality defence specification anodizing requirements, and the part was supplied to the customer with a F.A.I.R (First article inspection report).

This project illustrates our ability to tailor any manufacturing process to the needs of the client; resting the part after machining was unusual for us, as most clients want their component as quickly as possible, but allowing this part to rest ensured we were providing this client with the highest quality product that would meet their requirements satisfactorily.

The use of technology and highly precise engineering to manufacture a wide variety of products, as well as being able to tailor our manufacturing process to a client’s specifications, means that we can work with the most fastidious and exacting customers without issue.