Thompson precision engineers have been involved in component and assembly manufacturing since its incorporation in 1939 as a scientific instrument maker.

Thompson precision engineers have been involved in component and assembly manufacturing since its incorporation in 1939 as a scientific instrument maker.

We are the company to come to if you want our experience and expertise combined, this ensures you we offer the very best and most experienced precision engineering service every time. Our clients range from global brands to smaller operations and we are happy to hear from you wherever you are based in the world.

Whatever your requirements we will do our best to help, as a professional company our team are all highly trained in the latest technology and techniques available. We love working on all kinds of projects from the very simple and straightforward to the very complicated.

Experienced Precision Engineers

Our early work also included pioneering work on the very first versions of automotive paint spraying robots, along with revolutionary hydraulic motors and our own range of patented metal super finishing devices, which are still in manufacture and used around the world today.

Our early work also included pioneering work on the very first versions of automotive paint spraying robots, along with revolutionary hydraulic motors and our own range of patented metal super finishing devices, which are still in manufacture and used around the world today.

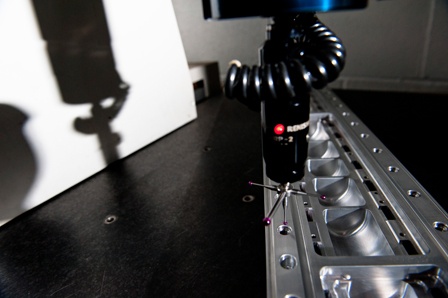

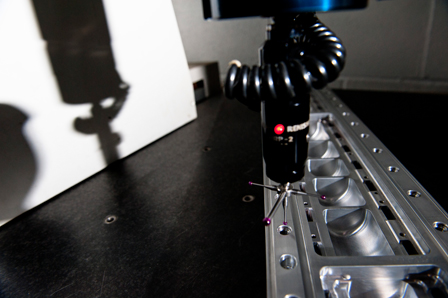

A full size range of CNC milling and CNC turning centres are supported by fully trained machinists using Delcam Power mill and Power shape. They are in turn backed up by two full time design engineers using Solidworks.

We will always deliver

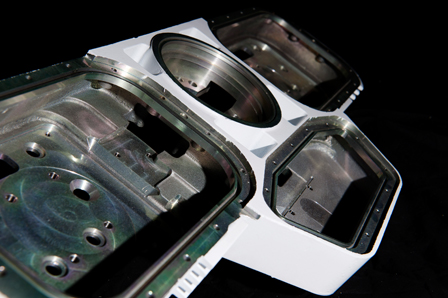

Large and small clients really value from our ability to deliver design assistance and production engineering advice at the point of manufacture whilst also being able to carry out entire design projects if required.

All of our management and production staff are dedicated professional precision engineers and all of us love to push the boundaries of what is technically possible. We have built up a reputation for taking on the most difficult projects and we have an impressive track record.

We can help you on all levels of precision engineering and we welcome you to bring us your project. We inspire to solve the project that looks impossible, with our company keeping abreast of the newest technologies and processes so that we are in the best position to tackle these projects from every angle. We won’t claim to do the impossible but we are always prepared to have a go.

Precision Engineering FAQs

Answer to some of the most commonly asked questions about precision engineering:

Precision engineering is a branch of engineering that deals with the design, manufacture, and operation of systems where extremely tight tolerances are required. This can include everything from micro-mechanical devices to aerospace components.

In many cases, precision engineering is necessary in order to create products that meet the highest standards of quality and performance. However, it can also be used to improve the efficiency of manufacturing processes or to create customised solutions for specific applications. Whatever the goal, precision engineering is a vital tool for anyone who needs to create precise, high-quality products.

Precision engineering is a highly skilled profession that requires both formal training, technical expertise and years of experience. The first step towards becoming a precision engineer is to obtain a relevant qualification, such as a degree in engineering or a related field. One way to get on the path to becoming a precision engineer is to complete an accredited engineering apprenticeship. Alternatively, candidates can achieve the required qualifications by completing a Level 3 BTEC in engineering or a similar qualification.

Once qualified, precision engineers must be able to work with a variety of tools and equipment. They must also be able to follow complex engineering drawings and instructions. In addition, precision engineers must be able to work independently and as part of a team. Simply having the right qualifications is not enough to guarantee success in this competitive field.

Precision engineers also need to have excellent problem-solving skills and be able to work effectively under pressure. In addition, they must be able to maintain a high level of accuracy and attention to detail. Those who combine these qualities with a strong work ethic and a willingness to learn will be well-positioned to build a successful career in precision engineering.

Precision engineering offers a number of benefits over traditional manufacturing methods:

- It allows for greater accuracy and repeatability. This means that products made using precision engineering are more likely to meet customer expectations and perform as intended.

- It can often be used to create products with more complex shapes or features than traditional methods would allow.

- Because precision engineering usually involves less material waste and fewer steps in the manufacturing process, it can often lead to reduced production costs.

As a result, precision engineering is becoming an increasingly popular choice for manufacturers across a wide range of industries.

Precision engineering is a field of engineering that deals with the manufacture of high-accuracy components and assemblies. The tolerances of these components are usually tight, in the range of microns or even nanometers. This requires the use of specialised machinery and tools that can work to very precise specifications.

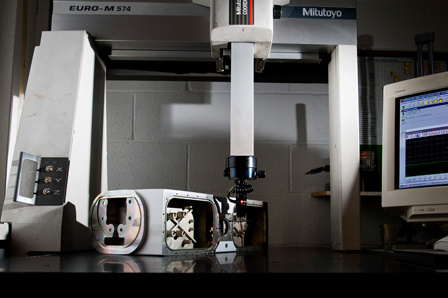

Some common examples of precision engineering machinery include computer numerically controlled (CNC) lathes, milling machines and grinding machines. These machines are operated by skilled technicians who understand how to produce components with the required level of accuracy. In addition to manufacturing equipment, precision engineers also use a variety of measuring devices to check components for accuracy. This includes microscopes, callipers and coordinate measuring machines.

By using the right tools and techniques, precision engineers can produce parts that meet the most demanding standards.

Precision engineering can be used on a variety of materials, including metals, plastics, and composites. In general, any material that can be machined to the required tolerance can be used for precision engineering. However, some materials are better suited to this process than others.

For example, metals such as aluminium, titanium, copper and stainless steel are often used in precision engineering because they can be machined to very tight tolerances without sacrificing strength or durability.

In contrast, plastics are not typically used for precision engineering because they are more difficult to work with and have lower tolerance levels.

Ultimately, the best material for precision engineering depends on the specific application and requirements.

Precision engineering is used in a wide range of industries, from aerospace to medicine. Products that are created using precision engineering must meet very strict tolerances, often less than a millimetre. In many cases, it is the only way to create certain products or components.

For example, without precision engineering it would be impossible to create the tiny parts needed for electronic devices such as smartphones. Similarly, medical implants and prosthetics must be created with extreme precision in order to function properly. Some other examples of items that can be created using precision engineering include medical implants, eyeglass lenses, and semiconductor chips.

In many cases, manufacturing using this method is essential in order to ensure that products meet certain safety or performance standards and precision engineering is essential for creating many of the products that we rely on every day. Take a look at our precision engineers gallery where you can see a range of projects that required precision engineering.

Yes we do! You can take a look at our precision engineering case studies here to see some of the challenging precision engineering jobs we have taken on, including a hydraulic valve and a heavy duty electronics enclosure.